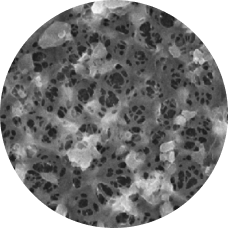

Lithium-ion battery separator is a polymer functional material with nanopores.

The performance of separator determines the interface structure and internal resistance of the battery, exerting a direct influence upon battery capacity, circulation, safety and other properties.

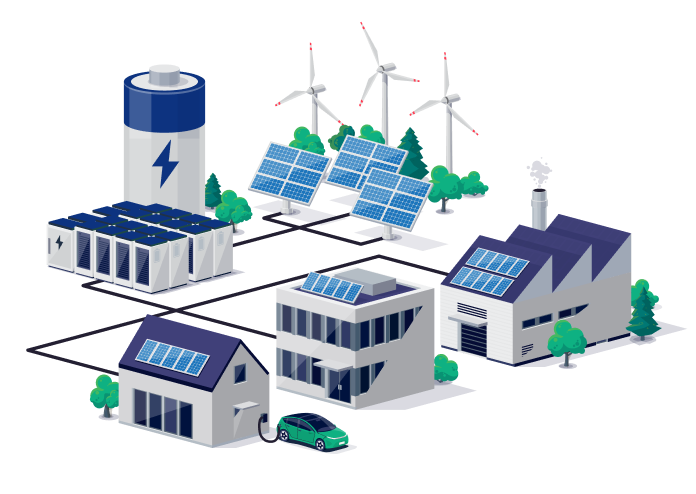

In view of the demands of power battery customers for high safety, high energy density and fast charging, SEMCORP provides customized high-strength separator, ultra-thin separator, low breathability separator; with high-performance base film as the basis matched with coatings of specific functions, we can meet the customers’needs for various power battery.

SEMCORP boasts industry-leading ultra-thin separator and advanced coating technology and provides customers with various solutions, which are mainly applied to traditional consumer electronics and emerging consumer electronic fields (drones, wearables, robots, etc.)

SEMCORP can provide, in view of the long cycle-life requirements for energy storage lithium-ion battery, energy storage battery separator of high retention liquid and long cycle-life, covering different fields such as electric power system energy storage, communication base station energy storage and family energy storage.

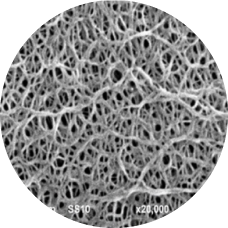

Biaxial stretching technique,which can produce high MD (longitudinal) and TD (transverse) strengths and relatively close values,can lower the risk of short circuit inside the battery caused by lithium metal dendrite puncture, improve the final yield of battery, and present more advantages in battery safety tests.

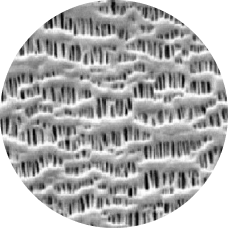

On the original base film (including dry and wet base film), ceramic materials such as high-purity nano-alumina or boehmite are applied onto the base film; one layer of ceramic surface, or one layer ceramic surface for each side, is coated.

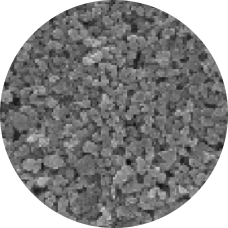

PVDF is dispersed (water-based) or dissolved (oil-based) and then applied evenly on the base film. When the separator is thermolaminated with the pole piece, PVDF-coating separator has larger effective contact area and presents good adhesion result (the adhesion strength of the coating ≥30N/m), thereby greatly reducing the defect rate of electrode products.